Commercial & Industrial Filters

Commercial and industrial filters are diverse, designed to meet specific requirements in various settings. Here are several types of filters commonly used in commercial and industrial applications:

Bag Filters: Bag filters are widely used in industrial dust collection systems to capture and remove airborne particulate matter. They are effective for high-volume applications and can handle a variety of dust types.

Cartridge Filters: Cartridge filters are used in both air and liquid filtration systems. They are efficient in capturing particles and contaminants, and their modular design allows for easy replacement.

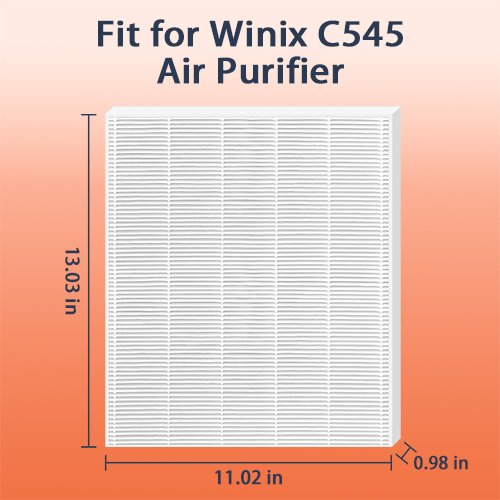

HEPA Filters (High-Efficiency Particulate Air): HEPA filters are employed in environments where extremely high filtration efficiency is required, such as cleanrooms, hospitals, and pharmaceutical manufacturing facilities. They capture very small particles, including bacteria and viruses. It usually be design in box, single header mini pleat and v bank style.

Activated Carbon Filters: Activated carbon filters are effective in adsorbing and removing gases, odors, and volatile organic compounds (VOCs). They find applications in air purification systems and industrial processes where gas removal is crucial.

Panel Filters: Panel filters are common in HVAC systems for commercial and industrial buildings. They come in various designs, including fiberglass and synthetic media, providing basic filtration for heating and cooling systems.

Pleated Filters: Pleated filters are versatile and used in various commercial and industrial settings. They offer a larger surface area for improved filtration efficiency and are available with different media types and MERV ratings.

V-Bank Filters: V-Bank filters, shaped like a V, are used in high-velocity air systems, such as HVAC units in commercial buildings. They provide high-efficiency filtration for demanding applications.

Pocket Filters: Pocket filters are designed with multiple pockets or bags of filtration media. They are used in HVAC systems and industrial air handling units, providing a balance between efficiency and airflow.

Oil Mist Filters: Oil mist filters are specifically designed for environments where oil mist is generated, such as machining and metalworking processes. They capture and remove oil mist from the air, maintaining a cleaner working environment.

Gas Phase Filters: Gas phase filters are used to remove specific gases and chemical vapors from the air. They are essential in environments where airborne chemicals pose a threat to health or safety.

Separator Filters: Separator filters are commonly used in compressed air systems to remove moisture and oil from the air. They help protect downstream equipment and improve the quality of compressed air.

Pre-Filters: Pre-filters are placed upstream of more specialized filters to capture larger particles and extend the life of subsequent filters. They are commonly used in air handling units and industrial processes.

Dust Collector Filters: Dust collector filters, including cartridge filters and bag filters, are utilized in industrial dust collection systems to capture and contain dust generated during manufacturing processes.

The selection of commercial and industrial filters depends on the specific application, air or liquid quality requirements, and the nature of the contaminants being addressed. It's crucial to consider factors such as filtration efficiency, pressure drop, and maintenance requirements when choosing the appropriate filter for a given industrial or commercial setting.