Pocket Filters in Air Filtration Systems

Air purification system construction and how to pick the right filtration mechanism is a basic and crucial matters. An essential piece in this puzzle is the pocket filter.

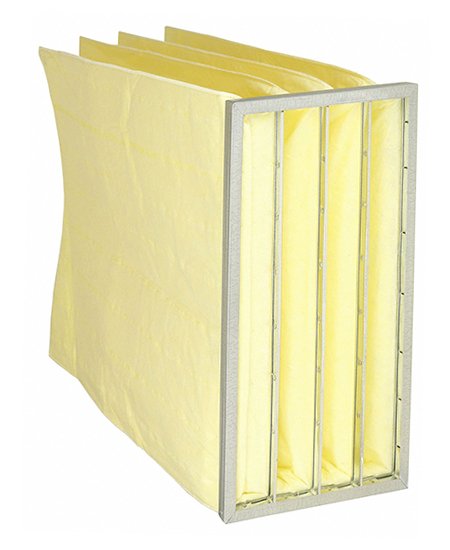

A pocket filter, as the name connotes, boasts individual pockets—each designed using a specific type of media playing a significant role in purifying the air. It contributes materially to the overall cleanliness of the environment it is installed in.

Constructed primarily from synthetic and fiberglass, progressive structure fibers, the media of pocket filters attract and retain particles in the air. They operate on principles of impingement and diffusion, forming the crux of their operational mechanism.

As air enters the pocket filter, it encounter the synthetic fibers—primary defenders against pollutants. The process of impingement and diffusion comes into play, resulting in the capture of both larger and smaller particles, making pocket filters epitomes of high fractional efficiency.

The pocket filters carry high dust-holding capacity, contributed by the volume of pockets they comprise, that is why air purification systems need pocket filters. Holding more impurities for extended periods enhances their longevity and efficiency. Furthermore, pocket filters are energy-efficient, thanks to the continuous synthetic fibers used in their construction, reducing operational costs.

These pocket filters have different efficiency grades, ranging from G4 to F9 as per EN779 Class, or from MERV 8 to MERV 16 as per ASHRAE 52.2 standard. The wide assortment ensures a pocket filter is available for specific purification requirements, promising a high particle-capture rate.

The applications of pocket filters span across sectors such as pharmaceuticals, food and beverage, and commercial HVAC systems, wherever optimum air quality is a priority. Their significant role in maintaining air purity, enhancing the lifespan of finer filters such as HEPA, and improving overall system efficiency makes them indispensable.