Baghouse Filters Plays a Crucial Role in Industrial Air Purification

When it's about the air around us, it becomes all the more critical – preserving our health and ensuring our well-being. Among the available options to purify air industry-wise, baghouse filters have been achieving great recognition. Let's delve deep into the world of baghouse filters, knowing about its functionalities, why they need filters, what material comprises them, understanding how it helps us, and some tips to choose an ideal one.

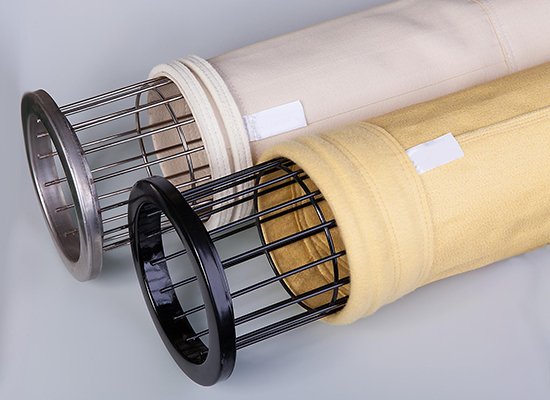

Baghouse filters, also known as bag filters or fabric filters, are air pollution control devices. They are exceptionally efficient and flexible, making them an optimal solution for various industries, including but not limited to, cement factories, steel mills, power plants, and pharmaceutical manufacturers, where large volumes of high temperature gases are released.

The primary function of a baghouse filter is to separate particulate pollutants, which French engineer Ferdinand Frederic Henri Mois invented in 1975. But why does a baghouse need a filter? Herein lies its principal functionality. The process involves pushing the polluted air through a cloth, capturing the harmful particles present in the contaminated air stream.

More often than not, baghouse filters are made from a material known as 'fleece', which is a synthetic fabric. These materials are preferred due to their longevity and excellent performance in high temperatures and acidic or alkaline environments, which typical paper filters cannot withstand.

The filter works by forcing gas through the bag, thus collecting dust on the cloth's inner side, allowing clean air to pass through. The effectiveness of baghouse filters in removing particulate matter and harmful pollutants from the air is remarkable, with efficiency of up to 99.99%.

When choosing a baghouse filter, several factors need consideration. Foremost among these includes the filter's physical attributes such as size, shape and construction material. It's important that your filter choice is highly durable and able to withstand complex industrial environments. Its compatibility with the specific type of dust being removed should also be evaluated.

Other considerations should include the total lifecycle cost of the filter. Be sure to dive into details about ongoing maintenance and operational costs, including energy costs.

In conclusion, baghouse filters play a vital role in improving the air quality we breathe in different industrial settings, efficiently trapping harmful particles. Understanding their function, the importance of their filters, the materials used, and choosing the right one can significantly enhance their operational effectiveness and longevity. Hence, making the right choice matters the most. This blog aims to shed light on baghouse filters ensuring you perceive their importance in your everyday life.